An important reason for doing this blog is to measure the effectiveness of various green technologies and report on the results so other people have some idea about what works and what doesn't. In general, measuring CO2 emissions directly is difficult. I've been primarily measuring effectiveness by deploying a green technology, like a solar PV system, then measuring what my energy use is with the technology in place and calculating from that what amount of CO2 was saved. I've done this by taking the CO2 intensity (in kg. of CO2 per energy measure, for example kg. per kilowatt-hours or therms) and multiplying it by the amount of energy not used in the previous time period, say a year. It would be much easier if I could simply measure the amount of CO2 my lifestyle is emitting now and then measure again after the green technology is deployed, but that isn't possible. For some energy sources, like gas or gasoline, this could be done, but for others, like electricity, the CO2 emissions are some distance away and I could not get the measurement without some intermediary, like PG&E, reporting it to me.

Although it is not possible to directly measure the CO2 emissions reduction from the closed-cell foam reinsulating job we did, it is possible to see how effective the insulation is in reducing heat loss from the house without waiting a year to see how much less gas we use. There are a couple of ways this can be done. One simple way is to take a look at the roof on a cold winter morning when there is frost on it, and look for places where there are bare spots or areas where the frost is less thick. Bare or thin spots are an indication that heat is leaking out of the house through the insulation preventing frost from forming. A uniform frost coat indicates that no heat is leaking through the roof.

I don't have any pictures of the roof prior to the reinsulation, but I did check it out last year on a few cold January days. There were plenty of bare spots, and the frost coat itself wasn't very thick. That was an indication that the insulation was poor. Below you can see a picture I took in the middle of February, this year after the insulation job was done, when we had a few nights with temperatures in the 20F's:

As you can see, the frost coat is interrupted by vertical lines that run up and down the roof. While it is difficult to see on this blurry photo, some of the lines are much thicker than the others. But even the lines have some frost on them, unlike the situation before where there were bare patches all over the roof with no frost.

These lines are an example of thermal bridging. I've discussed thermal bridging before in this blog:

here,

here, and

here. After much agonizing, I decided not to try to address thermal bridging for the whole house in our system remodel because it would have been expensive and the contractor who is doing our work would be likely to screw it up. I did decide to do some thermal bridging work on the back wall where we found mold on a stud face, using

Thermablok. I wanted to reduce the possibility that warm air would condense moisture on the stud face and cause mold to form again. In fact, Paul, our contractor, did screw it up. He had the drywall installers apply the Thermablok tape without supervising it himself, and they ended up having to redo the job because they put a single 2" wide tape strip in the middle of the stud face when the stud was wider that 2" instead of applying multiple 2" wide strips to the entire stud face.

The thermal bridging you can see in the photo above comes from the beams in the ceiling, which act as heat conductors from inside to outside of the house. The beams are at around R-5 while the bays between them are now at R-30. The bays are clearly covered in a thick layer of frost. The beam areas have a thinner layer. Some of the beam areas are larger because we had large rafters installed to stabilize the roof ridge, which was shifting and causing the drywall to crack.

Another way to measure effectiveness is through thermal imaging. If you recall in

this post, I discussed the thermal imaging test we had done in 2008. We had another thermal imaging test done in February after the closed cell foam was installed. Unfortunately, the thermal imaging test sat at the testing office for three weeks until the drywall installers were almost done with hanging the drywall because our contractors were convinced there were no problems and I was simply too busy to track the results down. Fortunately, there are very few problem areas, and, as we'll see below, the major ones may be addressable from outside.

In most cases, the areas that showed up as problems in the 2008 imaging test (like above the fireplace or in the east family room wall near the outside door) had no issues this time, and there were some areas now that are new. One interesting comparison, though, is of the master bedroom west wall. Here's a picture from 2008:

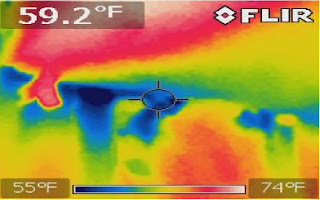

And here is the picture from the thermal imaging test done in Feburary after the new closed-cell foam insulation was installed:

The blue stripe down the middle in the top picture shows cold air leaking into the master bedroom through the back wall in 2008. In the bottom picture, the cold stripe has disappeared in 2011. The interesting thing is

we did not do any reinsulation in the master bedroom. The original report noted that the cold air leak was probably due to insulation that had pulled away from the stud, but we had that wall redone in 2006 when we had the master bedroom remodelled, so unless the contractor was completely incompetent (not an impossibility but probably not the case here), it is hard to see how the insulation could have slumped in that short a time.

Here is a picture of the east wall of the master bedroom from 2008, part of which is also captured on the left side of the picture from 2011 above:

You can see here cold air leaking in through the headers and down the stud at the junction between the two walls. All that has disappeared in the 2011 photo.

I suspect this improvement is due to the work that we did on the upstairs bedroom immediately above the master bedroom. We had the upstairs bedroom reinsulated with closed cell foam and we also had the ceiling of the small "attic", where the HRV is now located, immediately above the master bedroom reinsulated. What was probably happening was that cold air was leaking in through those areas, where the fiberglass batt was more than 30 years old and therefore in much worse condition than the batt insulation in the master bedroom, which was installed only 4 years ago. Since cold air is heavier than warm air, it likely flowed down through the fiberglass batt and along the studs. Fiberglass batt is not airtight, like closed cell foam.

One thing that hasn't changed is the front door, but that is not surprising because we had no work done on it. Here's a picture from 2008 of the threshold:

Here's a picture from 2011 of the same area:

Our front door has a metal threshold that acts as a heat conductor to the outside. Paul will replace this by a wood threshold (or at least we hope he will) near the end of the job when various finishing work is done.

Another problem area on the door is the upper left corner and left side. Here's a picture from 2008:

Here are two pictures showing the same area from 2011:

Again, the cold air leak is pretty obvious, though the area above the door shows less leakage because it is now much tighter.

There are a couple of spots in the family room where there appears to be air leaks that cause the studs to become significantly colder than simply from thermal bridging. Maybe air is leaking down along the studs somehow, despite the sealing that the closed cell foam is supposed to give. Here's the upper corner near the kitchen, on the west wall (and below that, the visible light picture):

This is a fairly complicated corner, and the kitchen area, behind the plastic, was not reinsulated so it is not surprising that there may be issues. I suspect an air leak coming from the outside, where there is some flashing loose above the small attached shed:

When the current circus has loaded up and left town, I'll get out my small spray foam can, spray the hole shut, and nail up a piece of flashing to close it off to the weather.

The back family room corner has a similar problem:

This is a cold spot along the beam at the bottom corner. I'm wondering if that could be from the missing piece of trim wood along the upper part of the house:

Of course, one would expect that the cold spot would show up at the top, but maybe the cold air is running down along the stud until it finds a place where there is some weakness in the insulation, or maybe it just pools on the outside of the house and cools down the stud. Paul thinks is may be from gaps in the footers, since in 1976 when this house was built they made no attempt to seal off the footers. In any case, I'm going to try sealing this one up from outside too, both at the top and bottom.

There are a few other spots where there is cold air coming in along a stud. One of the worst is in the living room, on the north wall. Here you can see three pictures where the cold air comes in along the corner and the through the footer. This one is on the upper corner:

This one is right below the above picture:

And here is along the footer:

The corner looks like below in visible light:

Again, it is a complicated corner. These may also be addressable from outside, perhaps spraying foam up into the crack between the siding and the footer, or something like that. And there may also be some kind of hole or something. The electrician did install a small FM radio antenna and left the hole uncaulked, but I doubt that hole was enough (I caulked it shut anyway but after the thermal imaging test was done).

The other leaks are in the upstairs bathroom and bedrooms. The bathroom has a leak right in the center of the outside wall through the studs:

The studs here are kind of complicated, so it does not surprise me that they may have missed it. On the other hand, it might be the old forced air duct in the middle of the picture. Maybe it is bridging to the outside. Here is a visible light picture of the same area:

We probably could have addressed this if I had received the thermal imaging before they started installing the drywall, but now of course it is too late.

There is also one on the ceiling in Bedroom1:

And the dormer corner on Bedroom2:

As well as two others, one in Bedroom3 and Bedroom2. These are probably impossible to address now, since they involve the roof.

Overall, the thermal leaks we found were not all that serious, with the exception of the ones in the living room and the ones in the family room, which may be addressable from outside. I can't say I'm happy that we didn't get the opportunity to do this right, but I'm not prepared to rip out the drywall again. At this point, after living 9 months in the back bedroom and kitchen and 4 months of rain and cold walking between them, I'm eager to get back in my house.