The HRV system was finally "completely" installed, by Duke's HVAC. Here's what I discovered on the back of the house one day a couple weeks ago when I got home from work:

The upper hood in the middle is the existing high speed bathroom ventilation. The ones on the lower left and right were meant to be the HRV intake and exhaust. Fantek customer support recommends that, on the same plane, the intake and exhaust vents should be at least 6 feet apart, and that the intake should be at least 6 feet from any other exhaust including attic vents. The maximum distance in this case is 3 feet between the bottom two vents, and 1.5 feet between the bottom two and the middle one.

When I complained to Paul, he asked where I wanted them. I considered what would be the easiest thing to do. There's very little room on the wall in the chase upstairs. The diagonal distance between the lower right hood on the picture and the upper left corner where the wall runs is maybe 5 1/2 feet. So I said why not put the intake on the roof, thinking perhaps it would have a longer pipe like a chimney.

Here is what we got:

The intake is so short it will draw in fumes from the asphalt shingles when they heat up.

I remeasured everything this morning but there is simply no way we can get 6 feet between the HRV exhaust, bathroom exhaust, an attic vent, and the HRV intake. It seems fairly clear that the bathroom exhaust needs to go out the roof vent, since it will be fairly strong. I also think the HRV exhaust will need to go through the roof, since I don't see any place where we can put it on the wall. The attic vent can stay on the right lower side of the back house wall in the picture above. That leaves the HRV intake. We could run a duct into the bedroom and out the bedroom wall, extending the chase we put in for the duct that runs to the hall. The extension would be below the wooden frame in this photo:

The vent would then run out the wall on the right side. Or we could simply put the duct at the upper corner of the attic area even though it is around 6" short. That might not be such a problem, since the attic vent won't be forcing air out like the exhaust. The hood will direct it downward and the intake will be much higher on the wall.

The front HRV is in better condition. There, I asked our good friend Duke to direct the intake through an existing attic vent in order to reduce the number of vents on the front of the house, but Fantek customer support tells me there needs to be a separate 6" hooded vent for the pressure to work. So we can just move the exhaust to the bottom below the attic vent, and put the intake where the exhaust is now. That way, the exhaust will not re-enter the house through the attic vent, and there is at least 8' between these vents and the intake.

One thing is for certain, though. You would have thought our good friend Duke would have given Fantek technical support a call before he started hacking around on the back side of our house. I'm certain at least one and possibly two of the holes need to be patched, either in place or by replacing the siding and cutting new holes.

The other problem is that I have an ominous feeling about the noise the HRV will generate. On Monday, I was working at home and several times a rumbling noise started up above my head. I think this was probably our good friend Duke starting up the HRV unit. I tried it again today and it was nowhere near as quiet as the unit Paul showed us at another job he did, when we were trying to decide if we wanted to put in HRV. Paul showed us an HRV installation he had done himself, in which the unit was hung from wires. No vibrations are transferred to the building structure. Running fully on, the HRV was absolutely quiet, and we requested that our unit be mounted similarly. But when I got home from a conference in Washington earlier this month, I found that our good friend Duke had used heavy metal bars to fasten this one down, though there were a couple of shock absorbers and some missing rubber gaskets which supposedly would cut down on the vibrations. He installed the rubber gaskets on Monday but if what I heard on Monday was the HRV, there still might be vibrations transferred to the house frame.

Sunday, November 28, 2010

Wednesday, November 24, 2010

Thermal Bridging

I've done some research on limiting thermal bridging. 25-27% of the interior surface in a typical stick-built building in the US consists of the face of the studs, headers, and other structural elements that extend through the walls from the inside to the outside. Our exterior sheathing is really simple due to the fact that the house was build in the 1970's before people understood about these things: one layer of plywood on the outside and tarpaper on the inside of the plywood to reduce moisture contact from rain and condensation. So the studs extend between the exterior sheathing and the interior drywall, acting as a major thermal bridge. Thermal bridging reduces the R-value of the walls by a considerable amount. A 2x4 stud is around R-4 while a 2x6 is around R-6. Even if the cavities between the studs are insulated with R-6/inch closed cell foam (for a cavity R-value of R-21 for a 2x4 wall or R-33 for a 2x6 wall), the impact on the wall assembly is a reduction in R-value of around 33%. For example, an R-19 insulated wall is reduced to R-12.8 by thermal bridging. Condensation on the interior surface of the studs and mold growth is a possibility. In fact, we found some minor mold growth on the interior studs of the back hallway wall. This wall gets no sun in winter at all, so it is possible that some condensation occurred during an especially cold winter night and never dried out the next day.

Thermal bridging is most evident in thermal imaging pictures. Consider this image taken of the master bedroom wall (unfortunately not being re-insulated at this time since we are living in it):

If you are interested in major problems, the bright blue along the corners where the walls and ceiling meet obviously draws the eye. These are places where the fiberglass batt insulation was improperly installed or has sagged with age (it is the former in this case, we had this room remodeled only 4 years ago). Major thermal leaks are occurring. But the thermal bridging effects of the studs can be seen in the dirty blue lines extending downward from the ceiling. These are the thermal traces of the studs. Reinsulating the wall with closed cell foam will get rid of the bright blue along the corners, but not the dirty blue below.

One very nice solution to thermal bridging is a product called Thermablok. The product is 4'x1.5"x0.4" strips of aerogel. The strips have a sticky side like tape, and are designed so that the backing can be removed and the strips simply stuck to the face of the studs. Aerogel is the best insulating material known, R-10 per inch, short of full vacuum. The R-value for a Thermablok strip is around R-4, effectively doubling the insulating power of a 2x4 stud. The cost is $1/linear foot or $4/strip, on the expensive side compared to materials like fiberglass batt or even spray foam.

I looked into Thermablok as a possible solution to thermal bridging in our house. A couple years ago, I made a thermal model of our house which required measuring all the walls. It is not perfectly accurate, but I think it gives a good estimate. The estimate of the area for the currently removed thermal envelope is 2520 sq. ft. At 25% stud area, the amount of stud area is 630 sq. ft. This would require 1261 4'x1.5" Thermablok strips, which, at $1/linear foot would be $5041, in addition to the labor to install it. And this price does not include the studs under the floor. This is pretty expensive. Besides that, as Paul mentioned when I brought up the topic in one of our meetings, rigid spray foam is rarely flush with the face of the studs, so there would be additional bridging through the rims of the studs that are exposed above the foam.

In an effort to find a cheaper solution, I googled around a bit for some more information. I found this reference which describes how to handle thermal bridging with normal insulating materials. Ideally, the external walls should be sheathed with extruded polystyrene board on the outside, but of course we can't do that. The recommendations that we could follow are:

The reference above doesn't mention under the floor, but I think we get thermal bridging through the floor too. So the same treatment as for the ceilings would probably be appropriate though it might be possible to use thinner strips to hold the rigid board in place and a 1"polyiso would be sufficient, since the crawlspace is already pretty tight and heat loss downwards isn't as serious as heat loss upwards.

I think the HRV chase upstairs would need a different treatment, because there simply isn't any space to get polyiso board in, besides which, it might crack and come loose when trying to crawl back into the space, for example, to service the HRV unit. I think that area could be done with Thermablok since it is relatively small. The area is around 38 sq. ft. and it would be about $76 for Thermablok. So I think it should be possible to install the Thermablok by hand and use some touch-up foam along the studs where the spray foam didn't cover to the top of the stud.

We also opened up an area from the outside under the living room window where we could do exterior sheathing. There is a large, exposed footer that will act as a major thermal bridge. I don't know if enough clearance exists for 1" rigid board, though, since the window assembly is already in place. Thermablok could probably be used in this area, since the amount would be relatively small. Since Thermablok is only 0.4" think, there should be less problem with clearance.

Unfortunately, we can't do anything about the footers and headers from the outside in the rest of the house because the siding is in place. We can mitigate bridging through the headers from the inside somewhat by ensuring the rigid board is sealed along the headers, and that gaps are filled with touchup foam, but we can't do anything about the footers because the floor is in place. We also can't do the wall between the garage/attic and hallway/kitchen because we had that redone several years ago and I was primarily interested at that point in simply reducing air infiltration to improve air quality, and not in reducing heat loss to the maximum extent possible.

Eliminating thermal bridging is one of the treatments necessary to build according to the German Passivhaus standard. The Passivhaus standard aims to get away with really minimal additional active heating and cooling, and uses HRV quite extensively. We are never going to turn our house into a Passivhaus, but I thought we could learn from what they do and try to get our carbon footprint down even further. So it was with visions of reducing our carbon footprint from heating by 50% instead of 30% dancing in my head that I emailed Paul with the above suggestions for eliminating thermal bridging in our job.

Unfortunately, The Lovely Wife brought those visions crashing down. Already annoyed by the length of time the job is taking and my tendency to want to make things right, she pointed out that the insulation contractors who Paul was soliciting for bids had probably never done thermal bridging elimination before. And the drywall contractors probably hadn't dealt with trying to fasten drywall when the walls were sheathed in polystyrene board. Considering the fact that our HRV contractor screwed up some fairly simple aspects of the installation which he could have had right by calling the manufacturer's technical support (see forthcoming post), the probability that the insulation contractor and drywall contractor would completely screw up any thermal bridging treatment was very high. In addition, all the electrical outlets are already in place, so if we put in 1" polystyrene sheathing, they would need to either be moved outward or extended somehow, to say nothing of the places were the drywall was not removed.

Sadly, I sent another email to Paul and told him to forget about the thermal bridging treatment, except on the back wall of the hallway. The mold indicates a major problem, so we'll confine the treatment to just that wall. Because it is such a limited space, Thermablok to cover it should not be so expensive, and any areas where the spray in foam failed to cover the stud can be touched up by hand with can foam.

Thermal bridging is most evident in thermal imaging pictures. Consider this image taken of the master bedroom wall (unfortunately not being re-insulated at this time since we are living in it):

If you are interested in major problems, the bright blue along the corners where the walls and ceiling meet obviously draws the eye. These are places where the fiberglass batt insulation was improperly installed or has sagged with age (it is the former in this case, we had this room remodeled only 4 years ago). Major thermal leaks are occurring. But the thermal bridging effects of the studs can be seen in the dirty blue lines extending downward from the ceiling. These are the thermal traces of the studs. Reinsulating the wall with closed cell foam will get rid of the bright blue along the corners, but not the dirty blue below.

One very nice solution to thermal bridging is a product called Thermablok. The product is 4'x1.5"x0.4" strips of aerogel. The strips have a sticky side like tape, and are designed so that the backing can be removed and the strips simply stuck to the face of the studs. Aerogel is the best insulating material known, R-10 per inch, short of full vacuum. The R-value for a Thermablok strip is around R-4, effectively doubling the insulating power of a 2x4 stud. The cost is $1/linear foot or $4/strip, on the expensive side compared to materials like fiberglass batt or even spray foam.

I looked into Thermablok as a possible solution to thermal bridging in our house. A couple years ago, I made a thermal model of our house which required measuring all the walls. It is not perfectly accurate, but I think it gives a good estimate. The estimate of the area for the currently removed thermal envelope is 2520 sq. ft. At 25% stud area, the amount of stud area is 630 sq. ft. This would require 1261 4'x1.5" Thermablok strips, which, at $1/linear foot would be $5041, in addition to the labor to install it. And this price does not include the studs under the floor. This is pretty expensive. Besides that, as Paul mentioned when I brought up the topic in one of our meetings, rigid spray foam is rarely flush with the face of the studs, so there would be additional bridging through the rims of the studs that are exposed above the foam.

In an effort to find a cheaper solution, I googled around a bit for some more information. I found this reference which describes how to handle thermal bridging with normal insulating materials. Ideally, the external walls should be sheathed with extruded polystyrene board on the outside, but of course we can't do that. The recommendations that we could follow are:

- On the ceilings, 2" foil-faced rigid polyisocyanate board as sheathing on the inside held in place with 1x4 furring strips, 16" on centers

- On walls if you can't use exterior sheathing , 1" polystyrene board (XPS) held in place with 1x4 furring strips, but I think maybe polyisocyanate could be used there too since I think it is a greener material than polystyrene and has a slightly higher R-value.

The reference above doesn't mention under the floor, but I think we get thermal bridging through the floor too. So the same treatment as for the ceilings would probably be appropriate though it might be possible to use thinner strips to hold the rigid board in place and a 1"polyiso would be sufficient, since the crawlspace is already pretty tight and heat loss downwards isn't as serious as heat loss upwards.

I think the HRV chase upstairs would need a different treatment, because there simply isn't any space to get polyiso board in, besides which, it might crack and come loose when trying to crawl back into the space, for example, to service the HRV unit. I think that area could be done with Thermablok since it is relatively small. The area is around 38 sq. ft. and it would be about $76 for Thermablok. So I think it should be possible to install the Thermablok by hand and use some touch-up foam along the studs where the spray foam didn't cover to the top of the stud.

We also opened up an area from the outside under the living room window where we could do exterior sheathing. There is a large, exposed footer that will act as a major thermal bridge. I don't know if enough clearance exists for 1" rigid board, though, since the window assembly is already in place. Thermablok could probably be used in this area, since the amount would be relatively small. Since Thermablok is only 0.4" think, there should be less problem with clearance.

Unfortunately, we can't do anything about the footers and headers from the outside in the rest of the house because the siding is in place. We can mitigate bridging through the headers from the inside somewhat by ensuring the rigid board is sealed along the headers, and that gaps are filled with touchup foam, but we can't do anything about the footers because the floor is in place. We also can't do the wall between the garage/attic and hallway/kitchen because we had that redone several years ago and I was primarily interested at that point in simply reducing air infiltration to improve air quality, and not in reducing heat loss to the maximum extent possible.

Eliminating thermal bridging is one of the treatments necessary to build according to the German Passivhaus standard. The Passivhaus standard aims to get away with really minimal additional active heating and cooling, and uses HRV quite extensively. We are never going to turn our house into a Passivhaus, but I thought we could learn from what they do and try to get our carbon footprint down even further. So it was with visions of reducing our carbon footprint from heating by 50% instead of 30% dancing in my head that I emailed Paul with the above suggestions for eliminating thermal bridging in our job.

Unfortunately, The Lovely Wife brought those visions crashing down. Already annoyed by the length of time the job is taking and my tendency to want to make things right, she pointed out that the insulation contractors who Paul was soliciting for bids had probably never done thermal bridging elimination before. And the drywall contractors probably hadn't dealt with trying to fasten drywall when the walls were sheathed in polystyrene board. Considering the fact that our HRV contractor screwed up some fairly simple aspects of the installation which he could have had right by calling the manufacturer's technical support (see forthcoming post), the probability that the insulation contractor and drywall contractor would completely screw up any thermal bridging treatment was very high. In addition, all the electrical outlets are already in place, so if we put in 1" polystyrene sheathing, they would need to either be moved outward or extended somehow, to say nothing of the places were the drywall was not removed.

Sadly, I sent another email to Paul and told him to forget about the thermal bridging treatment, except on the back wall of the hallway. The mold indicates a major problem, so we'll confine the treatment to just that wall. Because it is such a limited space, Thermablok to cover it should not be so expensive, and any areas where the spray in foam failed to cover the stud can be touched up by hand with can foam.

Saturday, November 20, 2010

Solar PV Design

The process of finalizing a design and a contract with a solar installer took an incredible three months. We've decided to go with REC Solar since their preliminary bid came the closest to what we wanted. We started the process in early August when I sent a rough description of the system to Forrest, our architect, and The Project Manager Who Shall Not Be Named. TPMWSNBN subsequently quit (or was gently fired, not sure which), but he hadn't done anything to start the process rolling anyway. Around the end of August, Christine put out the contract for bids. I had thought that TPMWSNBN had conveyed to her what I wanted but, after the bids came back, we realized that was not the case. As previously reported, one bid came from a roofer "wanting to get into solar installation" (we declined to pay for his training), one came from a nonprofit that sends volunteers up on your roof to install the system (our roof is quite steep and a professional roofer fell off when we had it replace in 2003, broke his collarbone, and required 3 operations), and a professional solar installer. Not surprisingly, the professional solar installer came closest to what we wanted, but it was not quite right. So we started the process over again sometime around the end of Sept.

One of the problems we have is that our job is not the typical situation that most solar installers face. Most people who get solar don't have any in the first place, and so the solar installer can take a year's worth of PG&E electrical usage data and come up with a good estimate about how the homeowner can eliminate 80% of their PG&E bill by installing solar. At which point, the homeowner is thrilled because the estimate shows them paying PG&E far less. In our case, we already have a solar PV system, so our bill tells the installer little about our electrical use. We still draw about 2000 kwh from the gird, but we pay nothing for that power because PG&E credits us around 3x for power generated on summer afternoons what we pay for power at night, when we are recharging our converted plug-in Prius, and in the winter, when we have lots of lights on and the furnace runs. We never use up the surplus credit, though we have been coming closer since we converted our 2008 Prius to a plug-in hybrid. We also are also primarily interested in completely offsetting the carbon footprint from our electricity usage, not in eliminating or reducing our electric bill, though of course that should follow if we completely offset the electricity usage.

In addition, we are having some new electric appliances installed, and are planning on buying a Nissan Leaf electric car next year. So we need somehow to plan a system that will offset our current grid draw and, in addition, offset the usage from the new appliances and the electric car if we want to eliminate our carbon footprint. Estimating the usage from the appliances is straightforward, but with the car, the electrical usage is likely to be somewhat more unpredictable. However, I came up with the following projected usage requiring offset in addition to the power provided by our current 2.5 kw system:

My original plan was to add a 30% margin to that to allow for power usage growth in the future. For example, if we revisit the decision not to install a geothermal heat pump, or even maybe go for an air source heat pump, we would then remain carbon neutral without having to install new panels. However, I found out near the end of the design process that PG&E won't allow solar installers to put in more panels than will completely offset the homeowner's electricity use, without good reason. Theoretically, this would not have allowed us to offset the new appliances or the Nissan Leaf because they weren't on our bill last year. REC and the other companies bidding on the contract kept sending bids for 18 panels, or 26 panels, until finally the REC engineer explained the problem. When I told them about our situation, the REC engineer accepted my explanation - that we were buying an electric car - as sufficient justification for a larger system. However, they would not let me include a 30% margin. This is unfortunate, because I was planning to offset the carbon generated by our gas hydronic furnace, gas stove, and new gas fireplace from the portion of the 30% margin that we didn't use. I guess we will just have to continue to buy carbon credits for that, as we are doing right now.

I also originally requested Sunpower E19 modules which generate 315 watts/panel, thinking that more watts per panel would reduce the number of panels and therefore the amount of space on my roof taken up by the PV system. However, Christine pointed out that the E19 was actually larger than standard modules, around 10" wider, though the same length. So, in effect, we would end up using about the same amount of roof space with the E19 as with a set of standard panels that generate 235 watts/panel, the maximum currently available in a standard-sized residential panel. REC also advised not to go with Sunpower, since they are a name brand and they charge extra for the brand. They instead recommended the Kyocera 235 watt module, the KD235GX-LFB. This model produces exactly the same amount of power as the Sunpower E18 series (which is standard sized) but is cheaper.

My original calculations, including the 30% margin, came up with a total system size of 6.85 kw DC. However, I failed to account for shading and losses due to AC conversion. When REC calculated the size of the system, it was 7.050 kw DC without the 30% margin. In either case, the number of panels is 30. As a practical matter, this is probably the maximum amount we can fit on the part of our roof that gets sufficient sun year round. You can see the problem in the picture below, which was screen-copied from the satellite photo of our roof from Google Maps (taken before the solar thermal system was installed on the east roof):

On the south end of the house (lower part of the picture) there is a huge hedge of redwoods in our neighbor's yard. These shade the south end of the house all year round. While we are certainly grateful for this shade in the hot California summer, in the winter, there is not enough sun on the south end for solar. So the entire array must be installed on the north end, on the west side roof - where you can see our 18 panel array today - and on the east side roof. REC is proposing to put 20 panels on the west side and 10 on the east side. This maximizes the number of panels that are exposed to sun during summer afternoons, when the net metering tariff is high. As a practical matter, 20 is probably the maximum that could be fit on the west side, due to the skylights and the solar-powered attic fan.

The next decision we needed to make was about inverters. An inverter changes the electric current from DC to 60 Hz AC (usually around 440 volts), which is compatible with the grid. The conversion process is relatively inefficient, losing around 12-15%, which is why REC's design calls for more DC power than my initial estimate. Our old system has a centralized inverter that sits on the side of our house, here you can see it:

When we had the old system installed, centralized inverters were the only technology available. Centralized inverters require the solar panels in each row to be wired up in series. The output side of one panel is connected to the input side of another and the entire system is then manually balanced so that the voltage seen by the inverter is the same for each row. The problem with this design is that shading, dirt, and irregular aging of the panels can cause the voltage from one or two panels in a string to drop, either transiently or permanently. Like a string of Christmas tree lights in which if one light goes out, they all go out, the entire string of panels is then cut out and the system loses power from all the panels in the string. The result is that the system can lose somewhere around 15-20% of total power output during a shading incident or permanently if the problem is due to irregular aging.

Recently, new technology has been developed to alleviate this problem. There are two different approaches:

MPP balancing systems use a centralized inverter, but each panel has a small control unit on it that measures the voltage and current. The control unit constantly adjusts the voltage and current so that the inverter sees exactly the right combination to maximize the energy generated by the system. The MPP balancing system can also determine whether the panel is experiencing accelerated aging or otherwise needs replacing, and report this through a Web interface (microinverters have this ability too). The capacitors in the control unit don't have to be very large and therefore don't need to be electrolytic. So MPP balancing systems typically have a longer warranty, usually 20 years. Still not the same as panels, but better.

When I was originally considering 315 watt panels, I discovered that nobody made a microinverter which handled more than 230 watts per panel, so I requested an MPP balancing system. Residental MPP balancing systems are not parametrized by the panel power rating but only depend on what the centralized inverter can handle. Tigo is one manufacturer of MPP balancing systems. Because MPP balancing systems are used more in large, commercial PV installations where ease of installation by relatively untrained personnel is not an issue, very few residential installers have much experience with them, so they either won't bid them or they have lots of reasons why such systems aren't as good as microinverters. I requested that Christine call up Tigo and another MPP balancing manufacturer and ask them for recommendations about solar installers that know how to install MPP systems.

After I found out about the increased panel size for the 315 watt panels and decided to go with the smaller 235 watt panels, I briefly considered switching to microinverters. But in addition to the issue of the short warranty, microinverters may have a thermal problem. The temperature under a solar panel in the summer is usually very high, maybe well above 100F. The inversion process itself generates heat, and the electronics become more inefficient as the temperature rises. Since a centralized inverter can be positioned where it is in the shade (as it is on our house), a lower temperature can be maintained. MPP balancing systems therefore have the potential to be more efficient in summer, when the PV system is generating the most energy. Because they don't handle such large amounts of electricity, they don't generate as much heat from the electronics. As a result, I requested that we stick with an MPP balancing system. REC has experience installing Tigo MPP balancing systems, which is another reason why we selected them.

REC's final projection was that the system would offset 101.65% of our electricity use and 90.04% of our bill. It's impossible to offset 100% of the bill because PG&E charges around $7/month for the privilege of connecting up to their system. Here's a table of REC's projections about our power use, solar production, current (actually projected) utility cost without solar, and projected utility cost with solar:

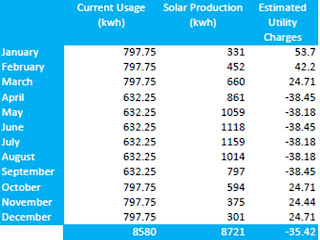

The chart shows that we only need to pay for electricity in January and February. In the other months, only PG&E's connect charge appears. The calculation isn't strictly accurate because the estimated usage is the same for each month. Since we'll only be using the on-demand hot water heater and HRV from October through March, the usage for those months should be higher, while the usage for the months April through September should be correspondingly lower. I recalculated the estimated usage and estimated utility charge with solar and came up with the following table:

My assumptions were:

One of the problems we have is that our job is not the typical situation that most solar installers face. Most people who get solar don't have any in the first place, and so the solar installer can take a year's worth of PG&E electrical usage data and come up with a good estimate about how the homeowner can eliminate 80% of their PG&E bill by installing solar. At which point, the homeowner is thrilled because the estimate shows them paying PG&E far less. In our case, we already have a solar PV system, so our bill tells the installer little about our electrical use. We still draw about 2000 kwh from the gird, but we pay nothing for that power because PG&E credits us around 3x for power generated on summer afternoons what we pay for power at night, when we are recharging our converted plug-in Prius, and in the winter, when we have lots of lights on and the furnace runs. We never use up the surplus credit, though we have been coming closer since we converted our 2008 Prius to a plug-in hybrid. We also are also primarily interested in completely offsetting the carbon footprint from our electricity usage, not in eliminating or reducing our electric bill, though of course that should follow if we completely offset the electricity usage.

In addition, we are having some new electric appliances installed, and are planning on buying a Nissan Leaf electric car next year. So we need somehow to plan a system that will offset our current grid draw and, in addition, offset the usage from the new appliances and the electric car if we want to eliminate our carbon footprint. Estimating the usage from the appliances is straightforward, but with the car, the electrical usage is likely to be somewhat more unpredictable. However, I came up with the following projected usage requiring offset in addition to the power provided by our current 2.5 kw system:

- 2000 kwh/year - current grid draw

- 360 kwh/year - HRV system used for 6 months in winter when the windows are closed, 24 hours per day

- 633 kwh/year - on-demand electric backup hot water heater. This was calculated by using the historical energy use from our gas-fired hot water heater, correcting for the (in)efficiency of gas-fired tank hot water heaters, and assuming that the backup heater would be needed for 6 months in winter.

- 2000 kwh/year - Nissan Leaf charging. This was calculated assuming 8,000 miles per year at 0.25 kwh/mile. We typically drive our commuter/around-town car about 8,000 miles per year and 0.25 kwh/mile is a standard figure that a reasonably aerodynamic electric car should achieve (it is slightly more than what Nissan assumes, since the Leaf has a 24 kwh battery and is supposed to get around 100 miles on a charge).

My original plan was to add a 30% margin to that to allow for power usage growth in the future. For example, if we revisit the decision not to install a geothermal heat pump, or even maybe go for an air source heat pump, we would then remain carbon neutral without having to install new panels. However, I found out near the end of the design process that PG&E won't allow solar installers to put in more panels than will completely offset the homeowner's electricity use, without good reason. Theoretically, this would not have allowed us to offset the new appliances or the Nissan Leaf because they weren't on our bill last year. REC and the other companies bidding on the contract kept sending bids for 18 panels, or 26 panels, until finally the REC engineer explained the problem. When I told them about our situation, the REC engineer accepted my explanation - that we were buying an electric car - as sufficient justification for a larger system. However, they would not let me include a 30% margin. This is unfortunate, because I was planning to offset the carbon generated by our gas hydronic furnace, gas stove, and new gas fireplace from the portion of the 30% margin that we didn't use. I guess we will just have to continue to buy carbon credits for that, as we are doing right now.

I also originally requested Sunpower E19 modules which generate 315 watts/panel, thinking that more watts per panel would reduce the number of panels and therefore the amount of space on my roof taken up by the PV system. However, Christine pointed out that the E19 was actually larger than standard modules, around 10" wider, though the same length. So, in effect, we would end up using about the same amount of roof space with the E19 as with a set of standard panels that generate 235 watts/panel, the maximum currently available in a standard-sized residential panel. REC also advised not to go with Sunpower, since they are a name brand and they charge extra for the brand. They instead recommended the Kyocera 235 watt module, the KD235GX-LFB. This model produces exactly the same amount of power as the Sunpower E18 series (which is standard sized) but is cheaper.

My original calculations, including the 30% margin, came up with a total system size of 6.85 kw DC. However, I failed to account for shading and losses due to AC conversion. When REC calculated the size of the system, it was 7.050 kw DC without the 30% margin. In either case, the number of panels is 30. As a practical matter, this is probably the maximum amount we can fit on the part of our roof that gets sufficient sun year round. You can see the problem in the picture below, which was screen-copied from the satellite photo of our roof from Google Maps (taken before the solar thermal system was installed on the east roof):

On the south end of the house (lower part of the picture) there is a huge hedge of redwoods in our neighbor's yard. These shade the south end of the house all year round. While we are certainly grateful for this shade in the hot California summer, in the winter, there is not enough sun on the south end for solar. So the entire array must be installed on the north end, on the west side roof - where you can see our 18 panel array today - and on the east side roof. REC is proposing to put 20 panels on the west side and 10 on the east side. This maximizes the number of panels that are exposed to sun during summer afternoons, when the net metering tariff is high. As a practical matter, 20 is probably the maximum that could be fit on the west side, due to the skylights and the solar-powered attic fan.

The next decision we needed to make was about inverters. An inverter changes the electric current from DC to 60 Hz AC (usually around 440 volts), which is compatible with the grid. The conversion process is relatively inefficient, losing around 12-15%, which is why REC's design calls for more DC power than my initial estimate. Our old system has a centralized inverter that sits on the side of our house, here you can see it:

When we had the old system installed, centralized inverters were the only technology available. Centralized inverters require the solar panels in each row to be wired up in series. The output side of one panel is connected to the input side of another and the entire system is then manually balanced so that the voltage seen by the inverter is the same for each row. The problem with this design is that shading, dirt, and irregular aging of the panels can cause the voltage from one or two panels in a string to drop, either transiently or permanently. Like a string of Christmas tree lights in which if one light goes out, they all go out, the entire string of panels is then cut out and the system loses power from all the panels in the string. The result is that the system can lose somewhere around 15-20% of total power output during a shading incident or permanently if the problem is due to irregular aging.

Recently, new technology has been developed to alleviate this problem. There are two different approaches:

- Microinverters - rather than having a centralized inverter, each panel has a separate microinverter on the panel and the electricity coming off the panel is AC instead of DC,

- Maximum Power Point (MPP) balancing - the electricity coming off the panels is still DC, but a control unit on the panels adjusts the voltage and current so that the inverter always sees the right combination to maximize power from the array.

MPP balancing systems use a centralized inverter, but each panel has a small control unit on it that measures the voltage and current. The control unit constantly adjusts the voltage and current so that the inverter sees exactly the right combination to maximize the energy generated by the system. The MPP balancing system can also determine whether the panel is experiencing accelerated aging or otherwise needs replacing, and report this through a Web interface (microinverters have this ability too). The capacitors in the control unit don't have to be very large and therefore don't need to be electrolytic. So MPP balancing systems typically have a longer warranty, usually 20 years. Still not the same as panels, but better.

When I was originally considering 315 watt panels, I discovered that nobody made a microinverter which handled more than 230 watts per panel, so I requested an MPP balancing system. Residental MPP balancing systems are not parametrized by the panel power rating but only depend on what the centralized inverter can handle. Tigo is one manufacturer of MPP balancing systems. Because MPP balancing systems are used more in large, commercial PV installations where ease of installation by relatively untrained personnel is not an issue, very few residential installers have much experience with them, so they either won't bid them or they have lots of reasons why such systems aren't as good as microinverters. I requested that Christine call up Tigo and another MPP balancing manufacturer and ask them for recommendations about solar installers that know how to install MPP systems.

After I found out about the increased panel size for the 315 watt panels and decided to go with the smaller 235 watt panels, I briefly considered switching to microinverters. But in addition to the issue of the short warranty, microinverters may have a thermal problem. The temperature under a solar panel in the summer is usually very high, maybe well above 100F. The inversion process itself generates heat, and the electronics become more inefficient as the temperature rises. Since a centralized inverter can be positioned where it is in the shade (as it is on our house), a lower temperature can be maintained. MPP balancing systems therefore have the potential to be more efficient in summer, when the PV system is generating the most energy. Because they don't handle such large amounts of electricity, they don't generate as much heat from the electronics. As a result, I requested that we stick with an MPP balancing system. REC has experience installing Tigo MPP balancing systems, which is another reason why we selected them.

REC's final projection was that the system would offset 101.65% of our electricity use and 90.04% of our bill. It's impossible to offset 100% of the bill because PG&E charges around $7/month for the privilege of connecting up to their system. Here's a table of REC's projections about our power use, solar production, current (actually projected) utility cost without solar, and projected utility cost with solar:

The chart shows that we only need to pay for electricity in January and February. In the other months, only PG&E's connect charge appears. The calculation isn't strictly accurate because the estimated usage is the same for each month. Since we'll only be using the on-demand hot water heater and HRV from October through March, the usage for those months should be higher, while the usage for the months April through September should be correspondingly lower. I recalculated the estimated usage and estimated utility charge with solar and came up with the following table:

My assumptions were:

- The 993 kwh/year usage from the HRV and the backup hot water heater were removed from the summer months and distributed evenly over the winter months,

- The 165.5 kwh/month thereby gained in the summer months were sold to PG&E for $0.28/kwh, the summer afternoon net meter tariff,

- The 165.5 kwh/month used in the winter were bought from PG&E for $0.10/kwh, slightly higher than the current PG&E winter tariff.

Saturday, November 13, 2010

Holes

Work seems to be progressing but mostly in the design space at the moment. The electrician finished up the low voltage wiring and all but one of the new 110V circuits. We have settled on a solar contractor and a rough set of specifications for the solar PV. The contractor is now working on a specific design and a bid. We have requested that the contractor have on-site at all times someone who has worked for the firm for at least one year, so we don't get burned again by an incompetent employee that was hired a few months ago. The insulation bids that were solicited by The Project Manager Who Shall Not Be Named were, as with most of the work he did, inadequate and Paul is re-soliciting based on my feedback. Our 200 amp upgrade request is in with PG&E and we are trying to find out the schedule. Projected completion is beginning of Feburary, but I believe that may stretch out depending on the solar PV installation schedule. But best of all: The Lovely Wife seems to be happy with progress!

I had a moment of concern that the extra 100 amps for our grid connect might not be enough after I found out that the on-demand hot water heater has three heating units, each of which requires 220V/40 amps. That is an enormous amount of power, 8.8 kilowatts, but applied over a very short period of time, maximum 20 minutes for a shower, so the net energy used is less, about 3 kilowatt-hours. The electric car charger only requires one 220V/40 amp circuit, but charges over a period of 6 hours. I did a rough calculation assuming a 440V/100 amp upgrade to the existing grid feed (440V/100 amps), which seems to be fine for our current set of appliances, and it should hand the on-demand water heater, electric car charger, and HRV (the HRV is peanuts, maybe 40 watts maximum).

I also did a short tour of the gutted interior looking for holes. One "feature" of older houses such as ours is the shoddy sealing of exterior penetrations. Here is an example:

The thin white line you see on the left side of the picture is a 1/4" to 1/2" gap between the dormer flashing and the building frame in the upstairs bathroom. This gap acts as a conduit for warm air to leak out of the building in winter. The fiberglass batt insulation that was in the stud bays here is completely inadequate to stop such leakage.

Gaps also occur between the interior wall space and the living space, as in this picture:

This picture was taken in the upstairs bathroom where the drywall was removed between the raised downstairs bathroom ceiling and the upstairs bathroom wall. The gray area is the back of the drywall on the light tray above the shower and toilet compartment doors in the downstairs bathroom. The white dust is plaster from drilling when the HRV vent was installed. The thin white line at the bottom is a 1/4" gap where the contractor failed to tape the drywall. This gap now acts as a conduit for smelly air from the bulk of the house to leak into the bathroom when the bathroom ventilation is on.

Another gap has even more serious effects:

I crawled into the unfinished attic next to the southeast bedroom upstairs where the HRV is now located. This picture was taken at the far end, where the uninsulated bathroom wall terminates the space. What you are looking at in the center of the photo is a large gap under the bedroom floor where the old forced air duct plunges under the floor toward the mechanical room where the old forced air furnace was located. The whitish yellow blob is insulation on the forced air duct. To the left of the gap, the space between the unfinished attic and the floor under the upstairs bedroom (which is over the ceiling of the master bedroom downstairs) is blocked off by a floor joist. But the gap for the forced air duct is completely open, and explains why, on summer nights, the downstairs master bedroom smelled like someone's old hiking boots. We had a pocket door installed in the master bedroom a few years ago. The interior of the pocket door is open into the wall cavity and not sealed. So on summer afternoons, when the upstairs unfinished attic is shaded and cool but the downstairs bedroom is warm, cool smelly air from the unfinished attic enters into the wall through this gap and out the pocket door enclosure.

Here's a gap that is not quite a hole:

This is between the fiberglass window frame and the wood frame of the house. There is no insulation here although the space is sealed on the outside, but this gap acts as a thermal wire, allowing warmth to escape from the house in winter.

The disturbing aspect of these last two examples is that they are in areas where we had contractors work in the 7 years since we owned the house. They are not from the original framing or from work done by previous owners. You would think that, in the 21st century, contractors would have some clue about building science and make sure that the work was up to the latest knowledge at best quality. But most contractors are clueless about how to properly insulate a building. They are still working with knowledge they gained in the 70's when they started working.

Finally, and example of the attitude toward proper insulation in the 70's when our house was built:

This picture was taken from outside the house, looking into the cavity under the tiled shelf under the living room windows. What you see here is a chunk of fiberglass insulation on the right side and the end of a chunk on the left (obscured by the wood frame). In the middle, is a huge gap, 4-6" wide, where an electrical wire runs and the drywall is visible. It is no wonder the tiles in the living room are icy cold in winter.

The picture is a perfect example of the attitude about proper thermal sealing in California in the the 1970's. It seems to be: "oh, California is such a mild climate and gas is cheap. Let's throw in a couple pieces of insulation here and there to say we did it. No need to do a through job". We saw exactly the same kind of shoddy insulation above our kitchen ceiling when we had a sun tunnel installed a couple years ago.

This example is why I disagree with people such as Matt Golden at Recurve, who claims that there is lots of "low hanging fruit" in energy efficiency. The number of houses that have no insulation at all and can be reinsulated at relatively low cost by drilling through the drywall and injecting blown in cellulose is far exceeded by the number with shoddly installed fiberglass batt insulation like ours. Most houses with no insulation were built before 1970 and there are far fewer of those than were built between, say, 1970 and 1995 or so with shoddily installed insulation. The cost and hassle of reinsulating a house like ours using the existing building technology, as we are finding out, far exceeds what most people are willing to go through.

I had a moment of concern that the extra 100 amps for our grid connect might not be enough after I found out that the on-demand hot water heater has three heating units, each of which requires 220V/40 amps. That is an enormous amount of power, 8.8 kilowatts, but applied over a very short period of time, maximum 20 minutes for a shower, so the net energy used is less, about 3 kilowatt-hours. The electric car charger only requires one 220V/40 amp circuit, but charges over a period of 6 hours. I did a rough calculation assuming a 440V/100 amp upgrade to the existing grid feed (440V/100 amps), which seems to be fine for our current set of appliances, and it should hand the on-demand water heater, electric car charger, and HRV (the HRV is peanuts, maybe 40 watts maximum).

I also did a short tour of the gutted interior looking for holes. One "feature" of older houses such as ours is the shoddy sealing of exterior penetrations. Here is an example:

The thin white line you see on the left side of the picture is a 1/4" to 1/2" gap between the dormer flashing and the building frame in the upstairs bathroom. This gap acts as a conduit for warm air to leak out of the building in winter. The fiberglass batt insulation that was in the stud bays here is completely inadequate to stop such leakage.

Gaps also occur between the interior wall space and the living space, as in this picture:

This picture was taken in the upstairs bathroom where the drywall was removed between the raised downstairs bathroom ceiling and the upstairs bathroom wall. The gray area is the back of the drywall on the light tray above the shower and toilet compartment doors in the downstairs bathroom. The white dust is plaster from drilling when the HRV vent was installed. The thin white line at the bottom is a 1/4" gap where the contractor failed to tape the drywall. This gap now acts as a conduit for smelly air from the bulk of the house to leak into the bathroom when the bathroom ventilation is on.

Another gap has even more serious effects:

I crawled into the unfinished attic next to the southeast bedroom upstairs where the HRV is now located. This picture was taken at the far end, where the uninsulated bathroom wall terminates the space. What you are looking at in the center of the photo is a large gap under the bedroom floor where the old forced air duct plunges under the floor toward the mechanical room where the old forced air furnace was located. The whitish yellow blob is insulation on the forced air duct. To the left of the gap, the space between the unfinished attic and the floor under the upstairs bedroom (which is over the ceiling of the master bedroom downstairs) is blocked off by a floor joist. But the gap for the forced air duct is completely open, and explains why, on summer nights, the downstairs master bedroom smelled like someone's old hiking boots. We had a pocket door installed in the master bedroom a few years ago. The interior of the pocket door is open into the wall cavity and not sealed. So on summer afternoons, when the upstairs unfinished attic is shaded and cool but the downstairs bedroom is warm, cool smelly air from the unfinished attic enters into the wall through this gap and out the pocket door enclosure.

Here's a gap that is not quite a hole:

This is between the fiberglass window frame and the wood frame of the house. There is no insulation here although the space is sealed on the outside, but this gap acts as a thermal wire, allowing warmth to escape from the house in winter.

The disturbing aspect of these last two examples is that they are in areas where we had contractors work in the 7 years since we owned the house. They are not from the original framing or from work done by previous owners. You would think that, in the 21st century, contractors would have some clue about building science and make sure that the work was up to the latest knowledge at best quality. But most contractors are clueless about how to properly insulate a building. They are still working with knowledge they gained in the 70's when they started working.

Finally, and example of the attitude toward proper insulation in the 70's when our house was built:

This picture was taken from outside the house, looking into the cavity under the tiled shelf under the living room windows. What you see here is a chunk of fiberglass insulation on the right side and the end of a chunk on the left (obscured by the wood frame). In the middle, is a huge gap, 4-6" wide, where an electrical wire runs and the drywall is visible. It is no wonder the tiles in the living room are icy cold in winter.

The picture is a perfect example of the attitude about proper thermal sealing in California in the the 1970's. It seems to be: "oh, California is such a mild climate and gas is cheap. Let's throw in a couple pieces of insulation here and there to say we did it. No need to do a through job". We saw exactly the same kind of shoddy insulation above our kitchen ceiling when we had a sun tunnel installed a couple years ago.

This example is why I disagree with people such as Matt Golden at Recurve, who claims that there is lots of "low hanging fruit" in energy efficiency. The number of houses that have no insulation at all and can be reinsulated at relatively low cost by drilling through the drywall and injecting blown in cellulose is far exceeded by the number with shoddly installed fiberglass batt insulation like ours. Most houses with no insulation were built before 1970 and there are far fewer of those than were built between, say, 1970 and 1995 or so with shoddily installed insulation. The cost and hassle of reinsulating a house like ours using the existing building technology, as we are finding out, far exceeds what most people are willing to go through.

Sunday, November 7, 2010

HRV, On-Demand Water Heater, and More!

I arrived back home after 2 weeks off-line on vacation last Sunday, and briefly checked out progress on the job. Then I immediately flew to Washington, DC, early the next day for a conference, coming home on Thurs. A lot has been done in the 2 weeks I was gone, more than in the previous 2 months. Today, I finally had time to poke around in more detail. Here's what's been happening.

Mold

Fiberglass batting is not air proof, air can leak through. When our roof was replaced in 2003, the builder did not install any ventilation under the plywood decking as buildingscience.com recommends. Ventilation allows the warm, moist air from inside to vent to the outside, but also of course results in energy loss through the thermal envelope. So in many places, warm indoor air came up against the cold roof decking in winter and condensation accumulated on the plywood. When the water remains more than 24 hours, mold will grow. We had many places on the decking where mold was growing, especially along the ridge in the hallway, since that is the highest spot in the house and is naturally where the hot air accumulates. There were also a couple places on the south side of the house with mold on studs and siding. Since I have a mold allergy (one of the many reasons why we are doing this remodel), I insisted that the mold be removed. We had a mold remediation company come in and treat the mold. The closed cell foam insulation that we are having installed doesn't allow air to penetrate, so it can be sprayed directly on the roof decking and siding to seal against air leakage.

Fireplace

Before we started the remodel, we had in our living room an old pellet stove without any thermostat that needed to be started by hand. I really wanted a newer model with thermostat and automatic starting, but Santa Clara County has a ban on wood burning appliances due to pollution during winter inversions. So we instead opted for a 90% AFUE gas Empire Comfort Mantis fireplace. This is about the most efficient gas fireplace that you can get. It has a condensing firebox that retrieves the heat of condensation from the steam formed by combustion, and takes combustion air from outside rather than within the home. The only downside is that it won't work when the grid is down because the outside venting requires a fan. But neither would a pellet stove, since it requires electricity for ignition and the screw that retrieves the pellet from the hopper.

On Fri., they installed the fireplace. Here's what it looks like without the copper surround:

Mold

Fiberglass batting is not air proof, air can leak through. When our roof was replaced in 2003, the builder did not install any ventilation under the plywood decking as buildingscience.com recommends. Ventilation allows the warm, moist air from inside to vent to the outside, but also of course results in energy loss through the thermal envelope. So in many places, warm indoor air came up against the cold roof decking in winter and condensation accumulated on the plywood. When the water remains more than 24 hours, mold will grow. We had many places on the decking where mold was growing, especially along the ridge in the hallway, since that is the highest spot in the house and is naturally where the hot air accumulates. There were also a couple places on the south side of the house with mold on studs and siding. Since I have a mold allergy (one of the many reasons why we are doing this remodel), I insisted that the mold be removed. We had a mold remediation company come in and treat the mold. The closed cell foam insulation that we are having installed doesn't allow air to penetrate, so it can be sprayed directly on the roof decking and siding to seal against air leakage.

Fireplace

Before we started the remodel, we had in our living room an old pellet stove without any thermostat that needed to be started by hand. I really wanted a newer model with thermostat and automatic starting, but Santa Clara County has a ban on wood burning appliances due to pollution during winter inversions. So we instead opted for a 90% AFUE gas Empire Comfort Mantis fireplace. This is about the most efficient gas fireplace that you can get. It has a condensing firebox that retrieves the heat of condensation from the steam formed by combustion, and takes combustion air from outside rather than within the home. The only downside is that it won't work when the grid is down because the outside venting requires a fan. But neither would a pellet stove, since it requires electricity for ignition and the screw that retrieves the pellet from the hopper.

On Fri., they installed the fireplace. Here's what it looks like without the copper surround:

and here is what the plumbing looks like coming out the back:

One pipe is for the combustion air intake, the other for the combustion gases exhaust. Unlike a lower efficiency furnace/fireplace, the combustion gases are not hot enough to simply float up a chimney and water would also condense out on a metal pipe, so a normal chimney/flue can't be used.

Structural Reinforcement

Another reason why we started this work was because the drywall along the ridge line in the hallway cathedral ceiling was cracking. Not just in small areas, a big gap opened up right along the ridge line from the front bedroom to the middle skylight and it would expand and contract depending on the temperature, raining down little bits of plaster when the temperature rose. Fixing this has turned out to be an enormous problem, and has been responsible for holding up the job for at least a month and a half. We have gone through two structural engineers trying to get some kind of solution that would immobilize the roof enough to prevent future cracking without having to take the roof off and put in new trusses. The basic problem is that the roof beams installed originally were not sturdy enough to support the weight of the skylights and the plywood decking without twisting some. Originally, the roof was wood shake shingles which are lighter, but we replaced it with composite shingles because they last longer, which required the plywood decking. This increased the weight of the roof. But even without the decking, the original roof supports are really not sturdy enough to support the full weight of the skylights - some of our neighbors with the same model house have a similar problem with cracking. It does not mean that the roof will collapse in a major earthquake, just that it is not stable against thermal expansion and minor movement.

The Project Manager Who Shall Not Be Named had the framers install metal plates at the joints but that was insufficient for some of the forces. So the new structural engineer and Paul came up with a series of what look like 10x4's that run up to the ridge beam and transfer some of the load onto the rafters further down:

Here you can see how the beam runs from the skylight, on the left, down along the rafters, on the right, distributing the weight of the skylight more evenly along the roof. The new beams are bolted to the rafters with heavy bolts:

Paul says that the beams will not likely prevent cracking during an earthquake but they will prevent the twisting with temperature and random minor movement which seemed to have caused the original problem.

HRV

The HRV system has been partially installed. We have two HRV units, one in the attic above the garage and one in a chase next to the east side upstairs bedroom. Here's a picture of the one in the chase:

The HRV unit is the Fantek SH704. The hard metal pipe running across above the unit is the existing bathroom ventilation from the downstairs master suite bath. The foil clad soft ducts on the left and the fiberglass clad ducts on the right are the new HRV ducting. The metal bar across the top is the mounting frame for the HRV.

When I first saw the metal bar, I was a bit upset. We had agreed to hang the HRV from wires in order to avoid transferring vibration to the house frame. After all, this unit is right above the master bedroom and next to another bedroom (which we use as The Lovely Wife's sewing studio) . It looked as if they had simply bolted the metal frame to the ceiling rafters and the HRV to the metal frame. However a closer inspection showed that the HRV apparently has a kind of shock absorber on it:

I think a rubber grommet is missing and must be installed yet in the shock absorber. So I'm willing to try it out to see whether or not there is any vibration.

Some details still must be worked out. The attic HRV, on the other side of the house, needs its humidity drain installed somewhere, and I'd like it to go into the new downspout that will be on that side of the house. And the intake and outlet vents on the chase HRV are uncomfortably close, and also close to the master bath venting:

I've asked Paul if we could locate the intake vent further up toward the roof peak where it it is less likely to draw in stale air from one of the exhaust ports. The new chase we installed running from the HRV chase to the hall exhaust vent seems to have enough room that one could run a second duct, depending on how large the duct is. The exterior venting has yet to be determined on the front side for the attic HRV. I've requested that they vent out where the existing attic vent is located, and vent in from the side of the garage. Not sure if they can do this, though, maybe higher on the attic wall would be better.

The interior ducting for the HRV looks like this:

Here the ducting runs in the chase next to the upstairs bedroom. An insulation guy is going to have to climb back in there to insulate the stud bays above the master bedroom and the back of the bathroom wall. It's a tight fit, I climbed back in there myself today. But because the ducts are flexible, you can shove them around, unlike standard forced air ducting. So I think it should be possible.

This next picture shows the chase in the front bedroom closet where the exhaust duct runs from the attic HRV to the exhaust vent in the hallway:

The framer put this chase in so we could run the HRV duct, and a similar one in the east side upstairs bedroom. The attic HRV draws in warm, stale air from the top of the cathedral hallway through the hall vent into this duct and exhaust it, after transferring the heat to fresh, incoming air. The vent cover for the HRV looks like this:

I've requested from Paul if we could get vent covers that look a little less intrusive. White on a colored wall is just too noticeable for my tastes.

On-Demand Electric Hot Water

The framer put in a closet above the upstairs bathroom door for the on-demand hot water heater and also for storage. The Tempra 20 Steibel-Eltron on-demand hot water heater was also installed, though it can't be actually hooked up to the power line until PG&E comes and installs 200 amp service:

Notice the lack of any venting? That is one nice thing about an electric hot water heater as opposed to gas. Because there is no combustion, it doesn't need venting, it's just another electric appliance like the washer or refrigerator. So we can use this closet like any other closet, for storage. It just happens to have a hot water heater in the back.

I checked out how the plumber fitted it into the solar hot water plumbing, and I am not quite sure if I understand. I've asked Paul to check. It should be in series with the solar plumbing, with the hot side of the solar tank running directly up to the on-demand heater, and the hot side of the on-demand heater running to the mixing valve downstairs and then into the domestic supply. This allows the hot water from the solar tank to rise up to the on-demand heater between use, eliminating a gout of cold water that enters the on-demand heater when a hot water tap is turned on, which could cause the on-demand heater to fire for a couple seconds till the flow from the solar tank hits it.

Some people, like Allison here at the energyvanguard.com, don't seem to like on-demand electric hot water heaters. I suppose, if they are not just being used as a backup to a solar thermal hot water system, they could be a problem, since they do use large amounts of electricity, especially if they need to heat the water from 60 degrees F or so to 120 degrees F. But when they are being used as backup, the incoming water is rarely below 100 degrees F and in summer, they won't be used at all. As my previous blog post showed, on-demand electric backup for solar becomes more carbon efficient than gas at some point *if* (and this is a big if) the grid is migrating to non-carbon energy sources. Of course, if you are offsetting the electricity use with home solar PV, as we are planning to do, then on-demand electric backup becomes essentially carbon free. It is also possible to offset a gas on-demand backup with solar PV too, but a gas on-demand heater then requires complex venting.

Next up: PG&E installation of the new 200 amp service, a decision on the solar PV installation and selection of an insulation contractor!

Subscribe to:

Comments (Atom)